Product Description

3030 board tester range is a scalable in-circuit test platform that delivers the shortest test time, superior diagnostic accuracy and full test coverage for the widest range of electronic products.

Inline automated or manual loading, con gurable, upgradable on eld and reliable over years, 3030 board tester range meets the test and throughput needs of electronic manufacturers worldwide.

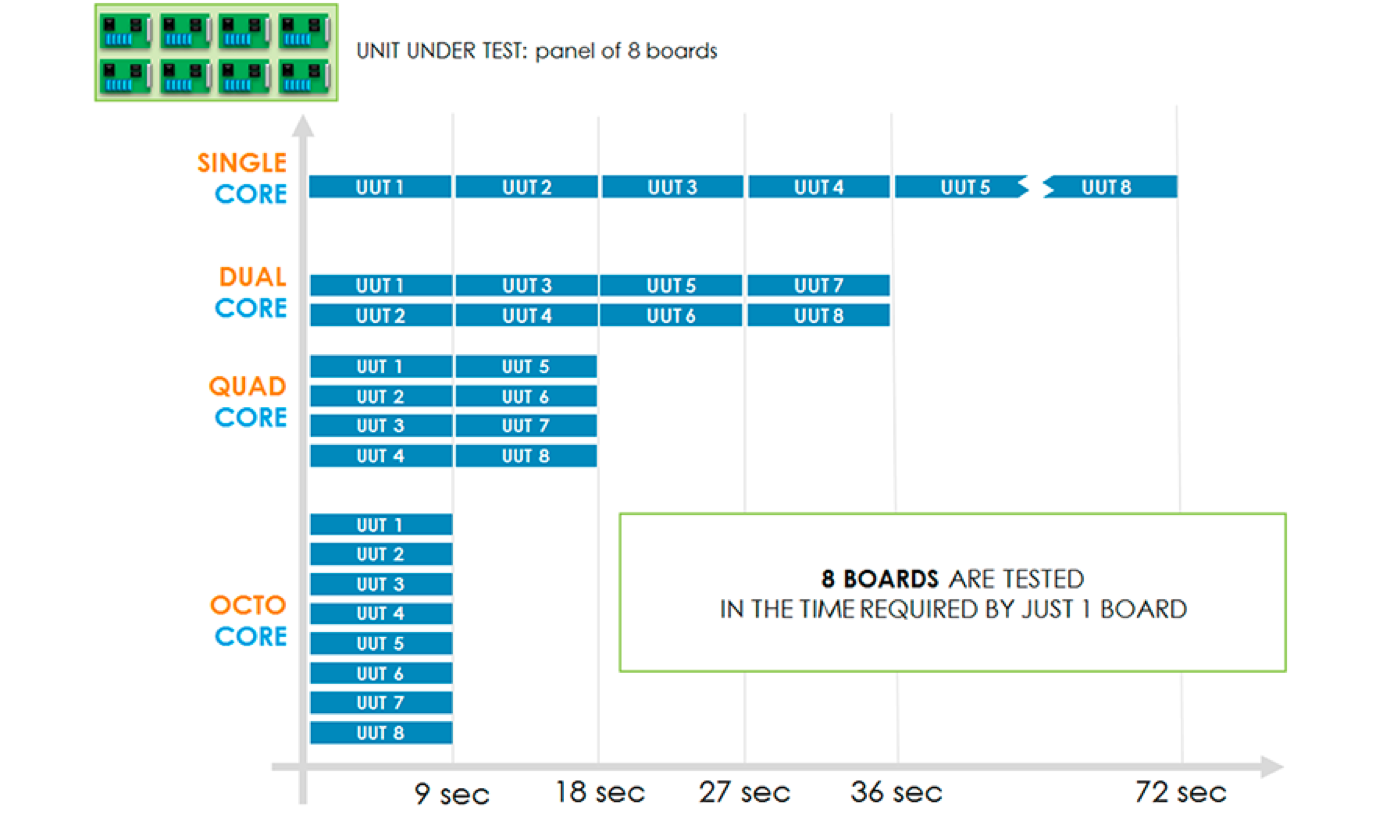

Multi-Core Architecture provides up to 8x greater productivity compared to conventional test equipment, dramatically lowering the cost of test.

Common hardware and software across the whole 3030 testers range mean same test result, easy test program migration and compatible spare parts.

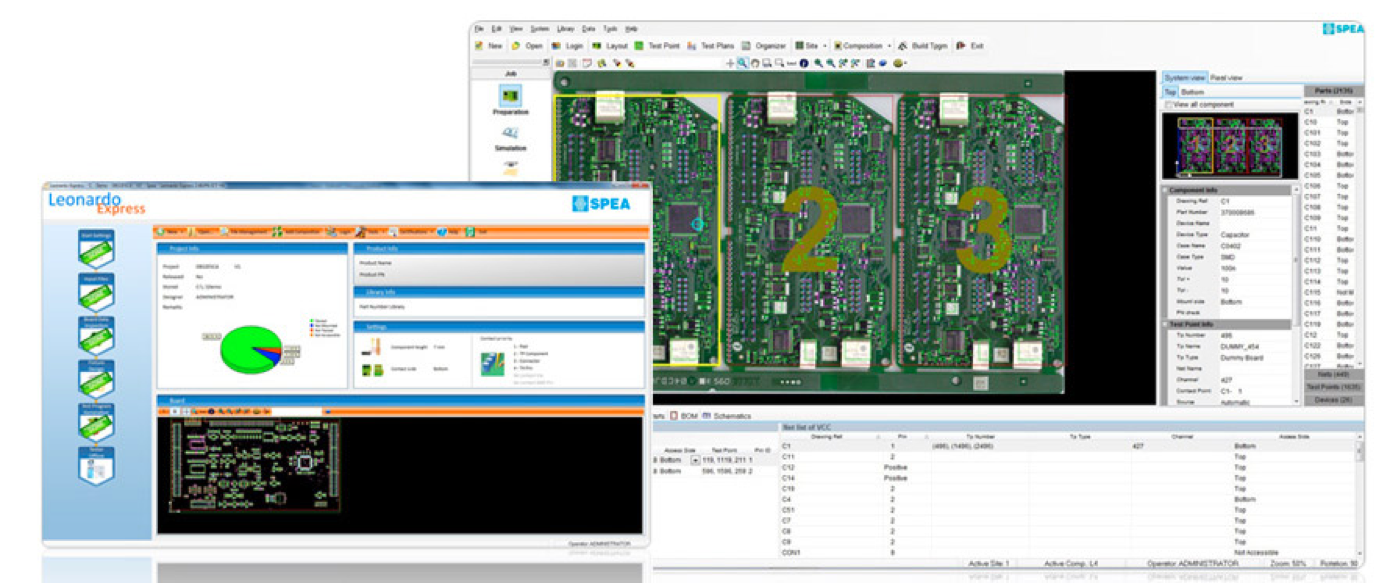

Test program generation is quick and automatic with Leonardo OS which enables unskilled user to develop a test program in a very short time.